Abstract

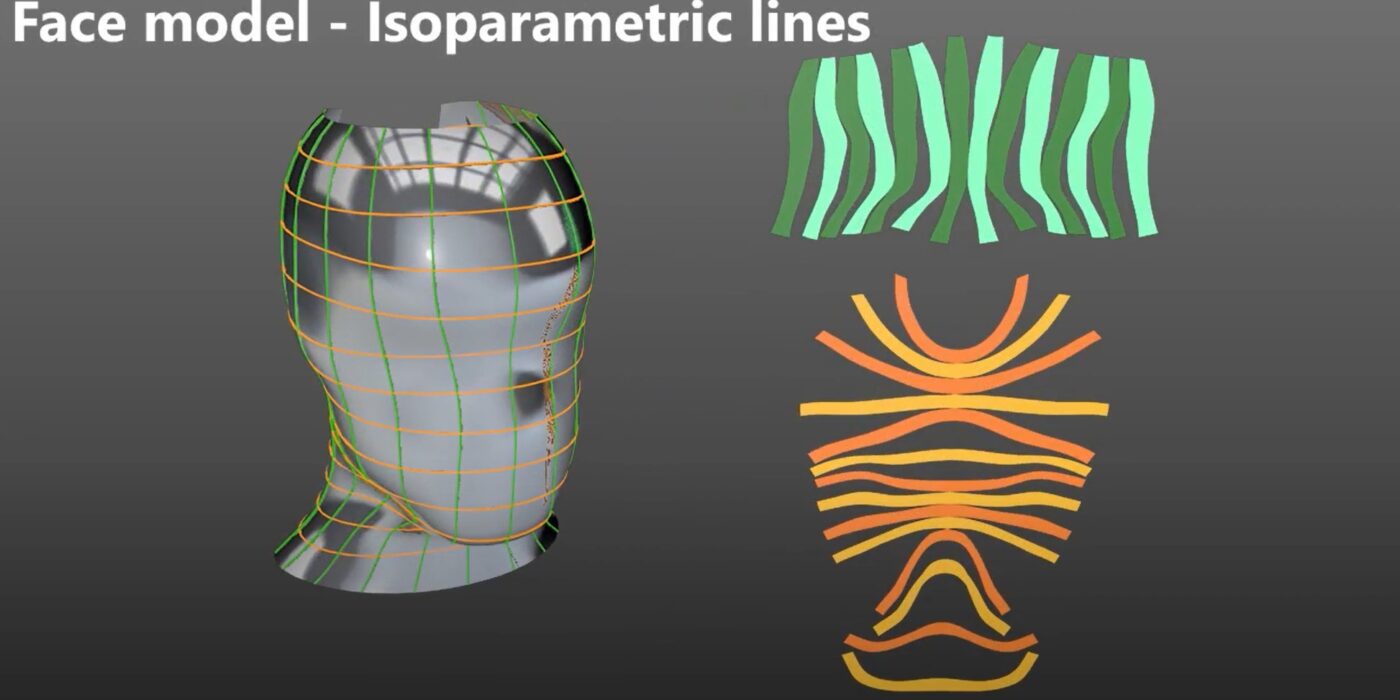

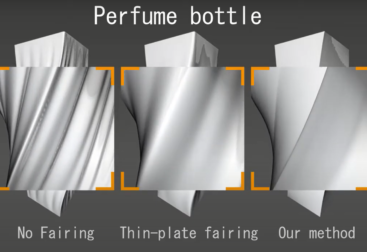

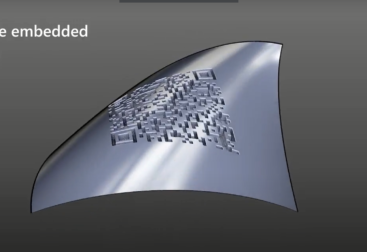

We introduce a fabrication method of doubly-curved shell structures by CFRP with control over fiber directions. Doubly-curved surfaces are tessellated into structured quadrilateral patches according to the purpose of use. One can design the tessellation in the parameter space, and map it to the 3D parametric surface, or use the orthogonal net of curves on surfaces such as lines of curvature, principal stretch lines, and principal stress lines. These patches, which we call generalized principal patches, are flattened onto a plane, and connected one by one by aligning the equi-length adjacent edges using translations and rotations forming generalized principal strips. Carbon fiber tows are placed onto these strips with one stroke by tailored fiber placement embroidery machines so that the fibers are not disconnected within strips. Preforms are stacked layer by layer into a mold of particular parts, and VaRTM or L-RTM method is employed to fabricate CFRP parts. We demonstrated the effectiveness of our proposed method by manufacturing an automobile hood and a marine propeller blade.